Structured Problem Solving Training

Structured Problem Solving Training

Courses last 2 days, and can be tailored to your bespoke requirements

Day 1: Covers the Theory.

Where tools and techniques are explained through discussion and workshops.

Day 2: Covers the Practical.

Where you get to apply the tools to your improvement opportunity or problem.

All delegates receive a CQual branded ‘Problem Solving Memory Jogger’ ®

The 7 step Structured Problem Solving approach to improved processes may be

used in several scenarios and can be broadly placed into 2 categories.

1. When things go wrong.

To resolve discrete problems, e.g., individual concerns.

To solve problems grouped into categories and ranked, for example by Pareto.

To address customer concerns. Shows you have a systematic methodical approach.

To deal with audit nonconformities such as those received during customer or third party assessments.

2. When improvement is desired.

Through application of this 7 step approach to Structured Problem Solving, improvements could be seen in process flow, throughput, delivery performance and customer satisfaction, with a positive impact on COPQ (Cost Of Poor Quality).

The 7 step approach can easily be aligned to your own corrective and risk-based preventive action systems.

CQual has used this 7 step approach for problem solving and process improvement to great effect for several years.

Many CQual clients have found the guide to Structured Problem Solving to be essential, seeing it as a vital component in their improvement toolbox when faced with challenging requirements.

My personal copy of PSMJ has been written on, highlighted, tabbed, and has a totally lived in look about it.

I encourage CQual clients to do the same, offering replacements when needed.

Learn More About Our Training Courses in this Case Study

Unfortunately mistakes are almost inevitable, but a system such as the 7 step approach to structured problem solving will:

Deliver a robust sustainable fix when things go wrong. Something your customer demands.

Provide a common approach aligned with efficient inter-departmental communication that your business can trust

Create the ability to engage employees in delivering common goals

Offer a ‘process approach’, using commonly available tools, with clear inputs and expected outputs

Enable your business to demonstrate a desire for improvement

Encourage the use of facts, evidence and data to solve problems on a range of projects

Provide a flexible system that your suppliers, employees and other interested parties can use effectively

Structured Problem Solving Training Course Contents:

Introduction to Structured Problem Solving,

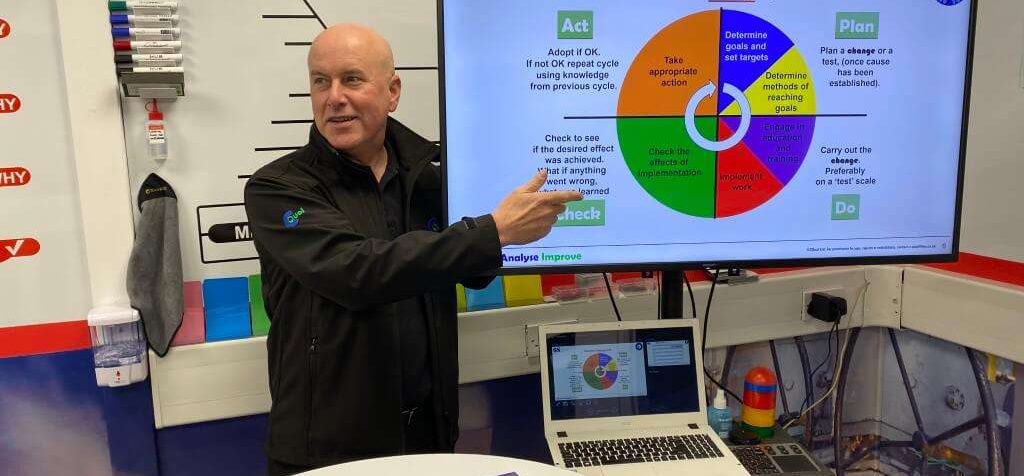

PDCA

Benefits and Barriers

Case Studies

Terminology and Link to ISO9001

Cost of Poor Quality (COPQ)

Building The Right Team

Basics of Measurement System Analysis

Understanding & writing Nonconformities

The Link to 'Lean' A3 Approach & Alternatives e.g. 8D

Process Mapping

Process Capability

Cause & Effect

Simple Quality Tools

Special & Common Causes

Root Cause Analysis

5 Whys

Human Factors

Human Failures

Error Proofing

Follow up and reflection

After Training Support via Zoom, Teams, Email, Telephone

Learn More About Our Training Courses in this Case Study